Alternatives to Engineered Stone

Engineered stone, also known as reconstituted stone and often referred to by popular brand names, has become the benchtop material of choice for homeowners across Australia, marketed as a durable, cost effective and aesthetically similar alternative to natural stone. Here we discuss why you should consider seeking alternatives to engineered stone and what your choices are.

There has been much recent press highlighting the dangers to stone workers in working with engineered stone. In it’s finished form, engineered stone poses no risk to homeowners, however there is considerable risk in cutting this material. Crystalline silica is a naturally occurring mineral in many construction materials including sand, stone, engineered stone etc., and the amount of crystalline silica found in products varies, with engineered stone containing the highest percentage at up to 95%.

This crystalline silica becomes airborne when products like engineered stone are cut and when the dust is inhaled the mineral makes its way deep into the respiratory system with life altering consequences. A combination of measures are required by stone workers to control exposure to crystalline silica, including wet processes and water suppression systems to prevent dust generation and disbursement. However, much like asbestos it is expected to be determined in the near future, that there may not be a safe way to work with engineered stone.

The best way we can minimise the risk to stone workers it is to choose to use a different material for your benchtop. Below, you will find a list of alternatives, in no particular order, to engineered stone that will not only give you beautiful benchtops and splashbacks, but also keep our construction workers safe.

Natural Stone

Natural stone contains a percentage of crystalline silica, although in significantly lower levels than that of engineered stone. For example marble contains around 5% (although can be as high as 30%), granite 30% and limestone 2%. Natural stone offers a stunning authentic alternative to engineered stone, although it does cost more. Being a natural product, there can be great variability in visual grain density, so make sure you hand select your slab.

Natural Stone: Dig Design’s Hannan Street project with Super White Dolomite benchtop, splashback and wrap.

Timber

A timber benchtop adds warmth to your kitchen and is very popular for bathroom vanities. With many timber species to choose from, you can select a colour and grain to suit your aesthetic. Timber is a softer finish to other materials, but it is easily refinished and resealed. The cost of timber benchtops varies depending on species, plank sizes and finish.

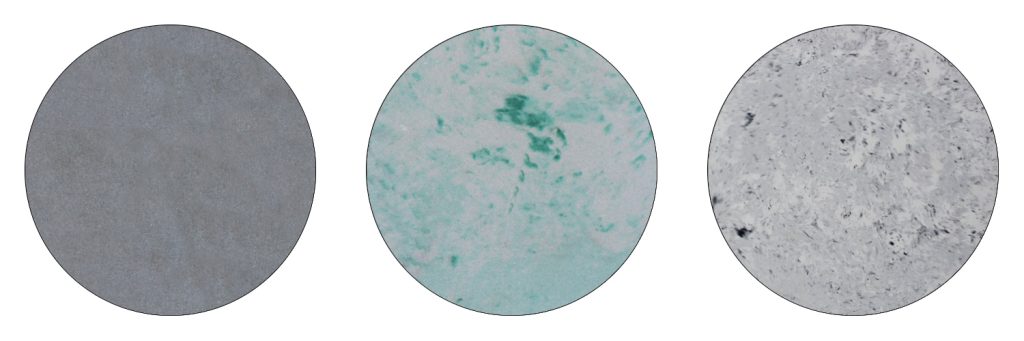

Concrete

A concrete benchtop can really add something special to your kitchen, and your kitchen doesn’t need an industrial aesthetic to showcase a concrete benchtop. Concrete benchtops can be pre-cast offsite or be formed and poured in situ. Concrete contains about 30% crystalline silica, a similar percentage to granite. Concrete benchtops are hardwearing and heat resistant and can be created in a variety of colours and finishes.

Stainless Steel

Stainless steel benchtops are durable and easy to clean and are most suited to an industrial aesthetic. They are prone to scratching and great care must be taken with abrasive products on the surface. Stainless steel benchtops are easily dented so don’t drop your heavy saucepan on them!

Solid Surface

Solid surface benchtops are crystalline silica free, made from bauxite and an acrylic resin binder. Slabs can be joined together using a method that makes them completely seamless, including sinks and drainers. They are UV resistant, stain resistant, scratch resistant and repairable. Available in many colourways, there is bound to be something to suit your aesthetic.

Porcelain

Porcelain is an ultra-compact surface that is increasing in popularity as a finish in Australian homes. It is heat and fire resistant as well as highly scratch and UV resistant, making it the perfect choice for outdoor kitchens. Porcelain benchtops contain around 15% quartz, the most common form of crystalline silica.

Porcelain: Dig Design’s Railway Crescent project with QuantumSix+ Statuario porcelain sheet wall cladding and shower shelf.

Recycled Glass

Benchtops made from recycled glass bottles are a sustainable, crystalline silica free alternative to engineered stone benchtops. Recycled glass benchtops are relatively new to the market and made from glass bottles and jars collected form our curb side recycled home waste, they are hand crafted and variance between and across slabs is to be expected … but also comes with the kudos of being able to tell your friends all about your recycled benchtop!

Laminate

Laminate technology has come a long way over the last decade or so, don’t think of laminate as your parent’s old 1970’s orange and brown kitchen. There are over one hundred realistic prints, textures and block colours to choose from, in many different finishes, including self-healing nano particle flat matte laminates. Laminate is not going to be for everyone, but don’t rule it out.

Laminate: Dig Design’s Verdon Street project with Fenix NTM (nano-tech matte) in Nero Ingo benchtop, splashback and cabinetry.

Low Crystalline Silica Engineered Stone

A new family of engineered stone benchtops are now coming to market, with a greatly reduced crystalline silica content of around 28%, a similar percentage to granite. This product is a hybrid, combining precision printed surface along with coordinated body veining.

You can see there are many great alternatives to engineered stone for you to choose from. There is bound to be one to suit your needs and make your kitchen or bathroom look just as beautiful as with engineered stone … except our stone workers will be kept safe. At Dig Design, we expect the availability of no or low crystalline silica products, such as that mentioned above, and the options available are set to increase over the next couple of years as informed consumers and designers force a change in the marketplace.

Contact us today to book a meeting to discuss how Dig Design can help you create your dream home.